All Regarding Industrial Scales: Secret Functions and Advantages for Your Workplace

Industrial ranges are critical in boosting functional effectiveness throughout different industries, using functions such as high capacity, precision accuracy, and robust building and construction. These tools not just reduce human error but additionally help with data integration and regulatory conformity, making them indispensable for quality assurance and product monitoring. As businesses progressively acknowledge the significance of these devices, the effects for performance and waste decrease end up being increasingly considerable. Recognizing the varied types and applications of commercial ranges can provide valuable insights into enhancing your workplace processes-- yet, the journey does not finish there.

Types of Industrial Scales

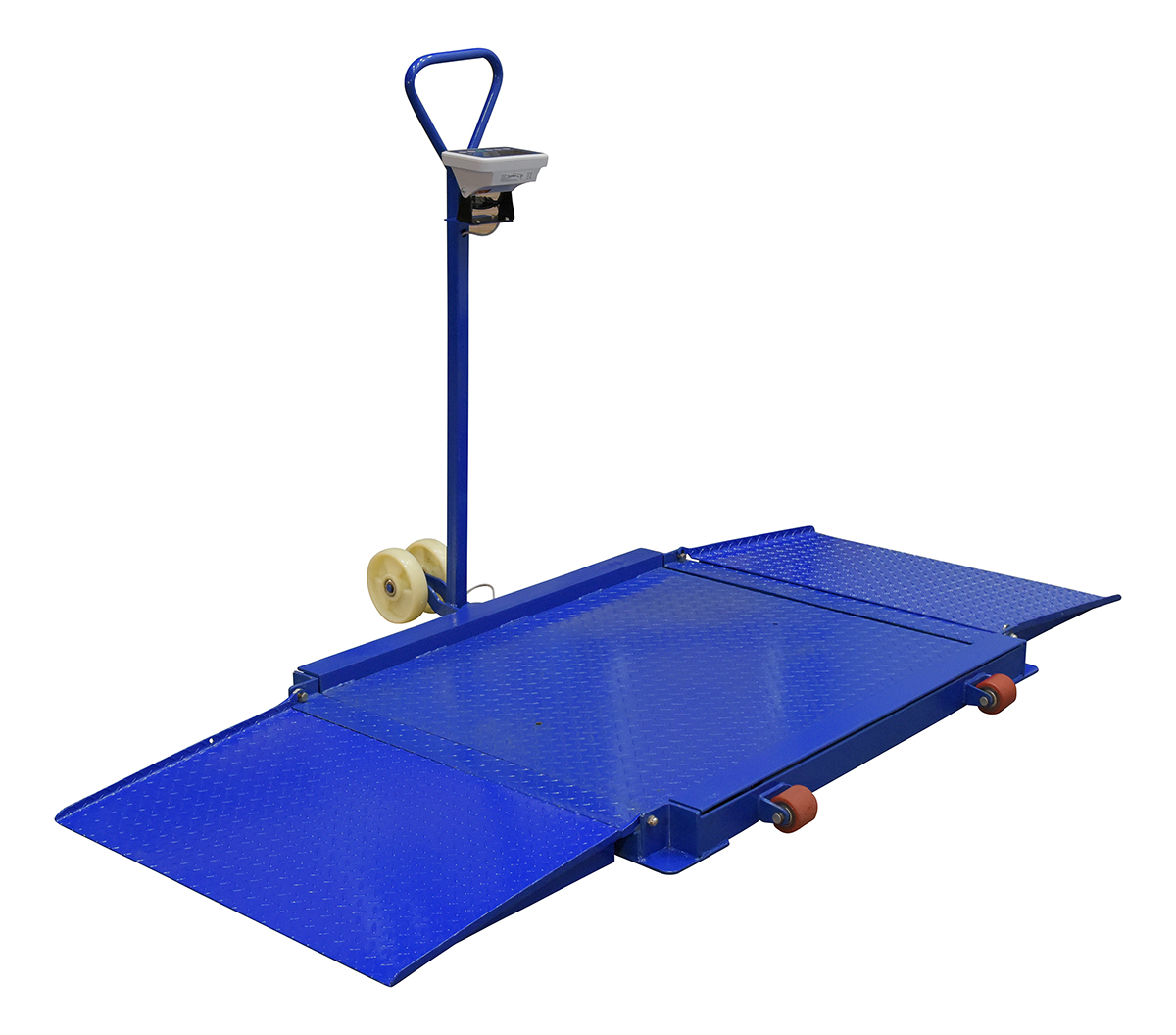

Industrial ranges are crucial devices used across numerous industries for exact weight measurement. One usual type is the platform range, which offers a large considering surface area perfect for heavy and bulky items.

One more prevalent kind is the bench range, which is ideal and small for smaller sized products. These scales are frequently discovered in retail and food service atmospheres, where fast and precise measurements are essential. Floor ranges offer a comparable purpose however are created for heavy-duty applications, enabling the considering of large pallets and containers directly on the ground.

Furthermore, electronic ranges have actually gained popularity as a result of their ease of use and precision. They often feature innovative electronic devices that improve functionality, such as connection choices for information monitoring. Additionally, mobile ranges offer adaptability for on-the-go considering, making them important in areas like agriculture and logistics.

Recognizing the numerous sorts of industrial ranges is crucial for choosing the right tools to fulfill specific operational demands, making certain performance and precision in weight measurement.

Secret Functions of Industrial Scales

When choosing the suitable kind of commercial scale, it is essential to take into consideration the crucial functions that enhance their functionality and viability for details applications. One of the most essential functions is the scale's ability. Industrial ranges are readily available in numerous weight abilities, making certain that they can suit the needs of different markets, from light materials to hefty loads.

Another essential attribute is accuracy. High-precision load cells are integral for making certain that dimensions are regular and trusted, which is crucial for supply management and quality assurance. Additionally, the readability of the screen plays a significant duty; clear, electronic display screens with adjustable illumination enable very easy viewing in numerous lighting problems.

Toughness is another essential characteristic, with several industrial scales made to hold up against severe environments, consisting of direct exposure to moisture, chemicals, and heavy use. Some designs also include water-proof or stainless-steel building and construction. Connection options such as Bluetooth or USB allow seamless information transfer and assimilation with various other systems.

Advantages for Ergonomics

Additionally, industrial ranges enable faster handling times. With automated evaluating solutions, staff members can promptly acquire Get More Info weight information without hand-operated estimations, liberating time for various other vital jobs. This velocity in workflow not only improves operational performance yet also helps satisfy manufacturing target dates much more successfully.

Furthermore, commercial scales provide useful data that can be evaluated for continuous renovation. By keeping an eye on weight trends, services can determine inefficiencies in their procedures and execute corrective actions, eventually causing improved efficiency.

The assimilation of these ranges likewise sustains compliance with sector guidelines, as precise coverage of weights is frequently needed. This minimizes the danger of costly penalties and enhances the business's credibility for dependability. Industrial Scales. On the whole, the unification of commercial ranges adds to a much more efficient, cost-efficient, and compliant workplace environment

Applications in Different Industries

In the food sector, industrial ranges are made use of for portion control, recipe formulation, and conformity with health and wellness regulations, assuring food safety and security and uniformity. In the pharmaceutical industry, precise weighing is crucial for medication solution, where you could look here also minor inconsistencies can lead to substantial governing concerns and safety issues.

Construction and logistics markets additionally take advantage of industrial scales, as they aid in enhancing and taking care of raw materials delivery procedures. By supplying exact weight data, these ranges facilitate better tons planning and conformity with transport guidelines.

In addition, the agricultural field uses industrial ranges for weighing produce, livestock, and feed, therefore boosting functional effectiveness and making sure reasonable trade practices.

Maintenance and Calibration Tips

To guarantee optimal efficiency and longevity of industrial scales, regular upkeep and calibration are important. Operators must regularly clean the scale to stop debris build-up, which can influence accuracy.

Calibration is similarly vital; it guarantees that the scale gives exact analyses according to market requirements. It is advisable to adjust ranges consistently-- at the very least annually or even more often if the range is made use of heavily or moved often. Comply with the manufacturer's standards for calibration treatments, which frequently consist of utilizing qualified calibration weights.

In addition, keeping appropriate environmental conditions, such as temperature and humidity control, can boost scale efficiency and accuracy. Lastly, training personnel on appropriate use methods will certainly even more guard against misuse that could result in inaccuracies or damage. By sticking to these maintenance and calibration ideas, companies can ensure their industrial scales run successfully, ultimately sustaining efficiency and compliance with regulative criteria.

Verdict

In recap, commercial scales offer as crucial tools for boosting work environment performance throughout diverse industries. By recognizing the crucial features i loved this and advantages of commercial ranges, companies can take advantage of these devices to enhance material usage, decrease waste, and inevitably drive performance.

Industrial ranges are pivotal in boosting functional efficiency across numerous markets, using attributes such as high capability, precision accuracy, and robust building and construction.When selecting the appropriate kind of commercial range, it is essential to consider the crucial features that boost their performance and suitability for specific applications. By giving exact weight dimensions, industrial ranges eliminate the capacity for human error, making sure that products are evaluated regularly and exactly. It is suggested to adjust scales on a regular basis-- at least when a year or even more regularly if the range is used greatly or moved regularly. By comprehending the essential attributes and benefits of industrial ranges, companies can utilize these devices to improve material utilization, minimize waste, and eventually drive efficiency.